LED digital tubes Meet Growing Demand for High-Reliability Displays

Industry Background and Market Demand

The demand for high-reliability display solutions has surged across industries, driven by the need for durability, energy efficiency, and superior visibility in harsh environments. LED digital tubes, a specialized segment of the display market, have gained prominence in applications where traditional LCD or OLED screens fall short. Sectors such as industrial automation, transportation, medical equipment, and outdoor signage increasingly rely on LED digital tubes for their robustness and long-term performance.

Market research indicates a steady growth trajectory for industrial-grade LED displays, with a projected CAGR of 6.8% from 2023 to 2030. This expansion is fueled by stricter regulatory standards, the push for energy-efficient technologies, and the rising adoption of automation in manufacturing and logistics. Unlike consumer-grade displays, LED digital tubes are engineered for continuous operation under extreme temperatures, high humidity, and mechanical stress—factors critical for mission-critical applications.

Core Technology and Working Principle

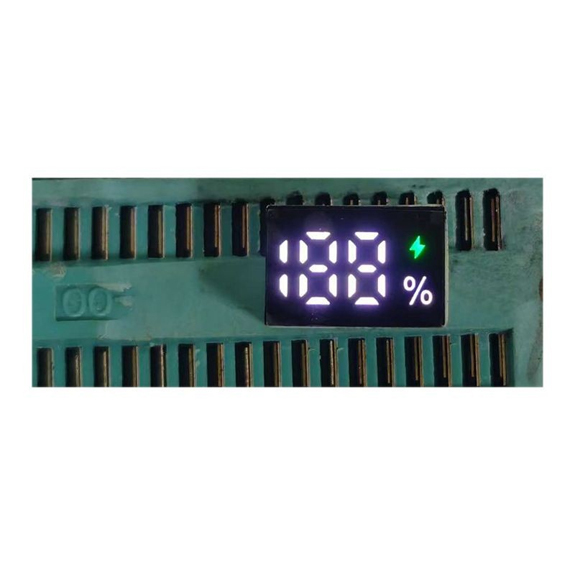

LED digital tubes are segmented displays composed of multiple light-emitting diodes (LEDs) arranged in a seven-segment or dot-matrix configuration. Each segment is individually controlled to display alphanumeric characters, symbols, or simple graphics. Unlike conventional displays, LED tubes prioritize clarity and longevity over high-resolution imagery, making them ideal for real-time data monitoring and control panels.

Key technological advancements include:

- High-Brightness LEDs: Utilizing InGaN (indium gallium nitride) or AlGaInP (aluminum gallium indium phosphide) semiconductors to achieve luminance levels exceeding 5,000 nits, ensuring readability in direct sunlight.

- Encapsulation Techniques: Epoxy resin or silicone coatings protect LED chips from moisture, dust, and thermal cycling, extending operational life beyond 100,000 hours.

- Drive Circuitry: Constant current drivers minimize flicker and ensure uniform brightness, even in low-temperature conditions.

Product Structure, Materials, and Manufacturing

A typical LED digital tube consists of:

1. LED Chips: Sourced from high-quality semiconductor suppliers to ensure consistent color and brightness.

2. PCB Substrate: FR-4 or metal-core PCBs provide thermal dissipation and mechanical stability.

3. Optical Diffuser: Polycarbonate or PMMA lenses enhance viewing angles while reducing glare.

4. Housing: Aluminum or reinforced plastic enclosures offer IP65 or higher ingress protection.

Manufacturing processes involve precision die-bonding, wire bonding, and automated optical inspection (AOI) to eliminate defects. Advanced surface-mount technology (SMT) ensures compact designs with minimal soldering failures.

Critical Factors Affecting Performance

Several variables determine the reliability of LED digital tubes:

- Thermal Management: Poor heat dissipation accelerates LED degradation. Metal-core PCBs and heat sinks are essential for high-power applications.

- Power Supply Stability: Voltage fluctuations cause premature failure. Isolated DC-DC converters are recommended for industrial use.

- Environmental Resistance: Sealing quality and material selection dictate performance in corrosive or high-vibration settings.

Supplier Selection and Supply Chain Considerations

Procuring high-reliability LED digital tubes requires evaluating:

- Certifications: Compliance with IEC 60529 (IP ratings), UL certification, and RoHS directives.

- Testing Protocols: Suppliers should provide MTBF (mean time between failures) data and accelerated life testing reports.

- Component Traceability: Reputable manufacturers disclose LED chip origins and batch testing records.

Common Challenges and Industry Pain Points

Despite their advantages, LED digital tubes face several challenges:

- Color Consistency: Variations in LED binning can lead to uneven displays, requiring strict quality control.

- Mechanical Stress: Vibration-prone environments demand shock-resistant designs.

- Legacy System Integration: Retrofitting older equipment may require custom driver interfaces.

Applications and Case Studies

1. Industrial Control Panels: A European automation firm replaced aging VFDs with LED digital tubes, reducing maintenance costs by 40% due to higher MTBF.

2. Public Transportation: LED-based passenger information systems in subways demonstrate 99.9% uptime in extreme weather conditions.

3. Medical Devices: Blood gas analyzers use LED tubes for fail-safe readability in critical care settings.

Future Trends and Innovations

Emerging developments include:

- Smart Displays: Integration with IoT for remote diagnostics and predictive maintenance.

- Flexible LED Tubes: Bendable PCBs enabling curved or compact installations.

- Energy Recovery Circuits: Regenerative drivers that recycle wasted heat into auxiliary power.

FAQ

Q: How do LED digital tubes compare to LCDs in outdoor environments?

A: LED tubes outperform LCDs in brightness, temperature tolerance, and lifespan, making them preferable for outdoor and industrial use.

Q: What is the typical lifespan of an industrial-grade LED digital tube?

A: High-quality units last 80,000–100,000 hours, contingent on thermal management and operating conditions.

Q: Are LED digital tubes customizable for specific voltage requirements?

A: Yes, most manufacturers offer 5V, 12V, or 24V variants, with custom driver options available.

By addressing the demand for rugged, energy-efficient displays, LED digital tubes are poised to remain a cornerstone of industrial and commercial applications. Continuous advancements in materials and manufacturing will further solidify their role in high-reliability environments.

286315373@qq.com

286315373@qq.com +86 18811889973

+86 18811889973

Phone

Phone

Comment

(0)