LED Numeric Modules Drive Better Feedback in Electric Power Controllers

Industry Background and Market Demand

Electric power controllers are critical in industrial automation, energy management, and smart grid systems, where real-time monitoring and precise feedback are essential. As industries demand higher efficiency and reliability, the need for improved human-machine interfaces (HMIs) has grown. LED numeric modules have emerged as a preferred solution for displaying critical parameters such as voltage, current, and power levels due to their high visibility, durability, and low power consumption.

The shift toward digitization and Industry 4.0 has accelerated the adoption of LED numeric displays in power control systems. Unlike traditional analog indicators, LED modules provide instant readability under varying lighting conditions, reducing operator errors. Market trends indicate a rising preference for modular designs that integrate seamlessly with programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems.

Core Technology: How LED Numeric Modules Enhance Feedback

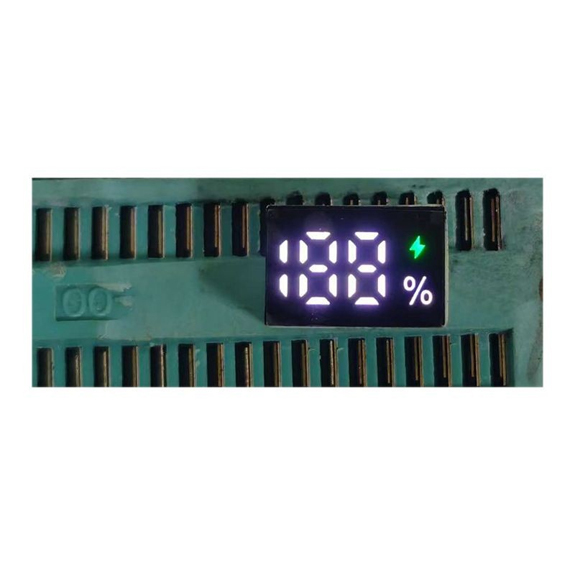

LED numeric modules are segmented displays that use light-emitting diodes to form digits, typically in 7-segment or 14-segment configurations. Their key advantages include:

- High Brightness and Contrast – Ensures readability in both low-light and high-ambient environments.

- Low Power Consumption – More energy-efficient than incandescent or fluorescent alternatives.

- Long Lifespan – LEDs last significantly longer than traditional bulbs, reducing maintenance costs.

- Fast Response Time – Critical for real-time monitoring in dynamic power control applications.

These modules often incorporate multiplexing techniques to reduce wiring complexity while maintaining display clarity. Advanced versions include embedded microcontrollers for dynamic brightness adjustment and error detection.

Product Structure, Materials, and Manufacturing

A typical LED numeric module consists of:

- LED Segments – High-intensity diodes arranged in digit patterns.

- Driver ICs – Control current flow to prevent overheating and ensure uniform brightness.

- PCB Substrate – Provides mechanical support and electrical connections.

- Encapsulation – Epoxy resin or polycarbonate housing for protection against dust, moisture, and mechanical stress.

Manufacturers prioritize materials with high thermal conductivity to dissipate heat effectively, as prolonged operation can degrade LED performance. Surface-mount technology (SMT) is commonly used for compact, high-density designs, while through-hole assembly remains prevalent in rugged industrial applications.

Key Factors Affecting Performance and Reliability

Several factors determine the effectiveness of LED numeric modules in power controllers:

1. Thermal Management – Excessive heat shortens LED lifespan; heat sinks or thermally conductive adhesives are often integrated.

2. Current Regulation – Overdriving LEDs reduces efficiency; constant-current drivers are essential.

3. Environmental Resistance – Industrial settings require IP65 or higher ingress protection against dust and moisture.

4. Optical Design – Diffusers and anti-glare coatings improve visibility without compromising brightness.

Supplier Selection and Supply Chain Considerations

When sourcing LED numeric modules, engineers evaluate suppliers based on:

- Certifications – Compliance with IEC, UL, or RoHS standards ensures safety and environmental compatibility.

- Customization Capabilities – Suppliers should offer tailored solutions for specific voltage ranges or communication protocols.

- Lead Time and Scalability – Reliable suppliers maintain consistent quality even during high-demand periods.

OEMs often prioritize suppliers with vertical integration—controlling everything from semiconductor fabrication to final assembly—to minimize defects and ensure traceability.

Common Challenges and Industry Pain Points

Despite their advantages, LED numeric modules face several challenges:

- Compatibility Issues – Older power controllers may lack digital interfaces, requiring retrofitting.

- Color Limitations – Monochromatic displays (typically red or green) may not suit all environments.

- Electromagnetic Interference (EMI) – Poor shielding can lead to signal noise in high-power applications.

Manufacturers address these issues through improved shielding techniques, multi-color LED options, and backward-compatible designs.

Applications and Use Cases

LED numeric modules are widely used in:

- Industrial Power Distribution – Displaying load currents and fault conditions in circuit breakers.

- Renewable Energy Systems – Monitoring solar inverter outputs and battery charge levels.

- Railway and Transportation – Providing real-time feedback in traction control systems.

A notable case involves a European smart grid operator that reduced diagnostic time by 30% after upgrading to LED-based displays with integrated fault logging.

Current Trends and Future Developments

Emerging trends include:

- Smart Displays – Integration with IoT for remote monitoring and predictive maintenance.

- Higher Resolution – Dot-matrix LED modules enabling alphanumeric and symbolic feedback.

- Energy Harvesting – Self-powered displays using ambient light or thermal energy.

Future advancements may focus on flexible LED substrates for curved control panels and ultra-low-power designs for battery-operated systems.

FAQ

Q: How do LED numeric modules compare to LCDs in power controllers?

A: LEDs offer better visibility in bright environments and wider temperature ranges, whereas LCDs consume less power but may suffer from slower response times.

Q: Can LED modules be customized for different voltage ranges?

A: Yes, most manufacturers provide variants supporting 5V, 12V, or 24V DC, with optional current-limiting resistors.

Q: What is the typical lifespan of an industrial-grade LED display?

A: High-quality modules last 50,000–100,000 hours, depending on thermal management and operating conditions.

By addressing critical feedback needs in power control systems, LED numeric modules continue to evolve as a robust, efficient solution for modern industrial applications.

286315373@qq.com

286315373@qq.com +86 18811889973

+86 18811889973

Phone

Phone

Comment

(0)